Mechanical Engineering

INTRO to ENGINEERING PAGES

Research and development in the engineering sciences is a huge undertaking, carried out by many tens of thousands of professionals. We have synthesized and organized some of the disciplines that are very promising and very important. While no one can predict where and how far each technology will evolve, it may be possible to obtain an aggregate picture of important groupings and therefore of where near-term progress is likely.

Information has been obtained from public sources, in particular, from the pages of research interests of the program managers of the US National Science Foundation, https://www.nsf.gov/, AFOSR, https://www.afosr.af.mil/, ARO, https://www.aro.ncren.net/main1.htm, ONR, https://www.onr.navy.mil/ and NASA, https://ails.arc.nasa.gov/AILS.html . These pages and the information therein are all public record.

By gathering these interests in one location, we hope to publicize the important work of these program managers in organizing a major portion of the research base of the United States, and to inform our readers of where current thinking is on technological and scientific progress. Most industrially sponsored research tends to be proprietary. One may expect, however, that the areas described below are representative of the state-of-the-art.

For our academic readers, these pages may suggest lines of research that are worth pursuing. Perhaps links between currently disjoint areas of research will become evident. Such research at the boundaries between disciplines can be very rewarding and should be pursued. For our industry-based readers, we hope that by viewing where engineering research is focusing its efforts, industry can look further ahead to where opportunities wait for innovative development. Perhaps some of the technological pushes being described in these pages can be merged with existing products and internal R&D, leading to the next product, or better yet, the next product line.

Various engineering disciplines will be presented. The discussion is geared to the expert. Also, look for information on specific products in the near future.

We welcome proposals from our readers to write specialist essays on their areas of technical expertise.

FLUID MECHANICS

Introduction (Army)

The performance of Army weapon systems that involve airborne vehicles or convecting liquids is greatly affected by the fluid motion and the resultant forces imparted to the vehicle. The study of fluid dynamics is, thus, of vital interest for the design, development, and performance enhancement of many Army systems. One weapon system important to the Army is rotorcraft vehicles, whose performance depends largely on a mature and sound understanding of the fluid dynamics of such vehicles in flight. This field of aerodynamics makes possible the tactical flight operations envisioned for the highly mobile Army of the 21st century. The goal of more accurate, stable, maneuverable, and longer-range munitions dictates the need for aerodynamics research for both gun-launched projectiles and tactical missiles.

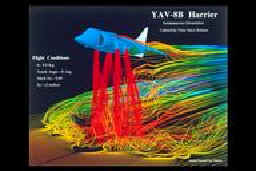

Flow Separation

Flow separation plays an important role in limiting the performance of many Army systems. Unsteady separation of boundary-layer fluid on the suction side of rotorcraft blades leads to dynamic stall on the retreating side of the rotor disk, with an attendant loss of lift and large negative pitching moment. Dynamic stall can be thought of as the pacing technical item inhibiting the development of agile super-manueverable rotorcraft. Flight regimes directly affected by this phenomenon include air combat, terrain following the nap-of-the-earth, and “shoot and scoot.” Missile and projectile base and afterbody flows often involve flow separation caused by control surfaces, shock waves, or discontinuous changes in body contour. Clearly, a thorough understanding of the various fluid dynamic mechanisms underlying flow separation can be used to tremendous advantage in the design of future Army systems, and the trend in the fluid dynamics program is to apply this fundamental knowledge to control this phenomena.

Accurate performance prediction of Army missiles and projectiles requires the ability to accurately predict the flowfield in the base region of these devices. While the modern techniques of computational fluid dynamics have made great contributions in this area, they are limited by the lack of accurate nonequilibrium turbulence models. It is difficult to formulate such models even for situations in which the flowfield has been well documented. In the case of missiles and projectiles operating at transonic and supersonic speeds, quantitative experimental measurements of the base-region flow are exceedingly difficult to perform accurately, and the task of the development and selection of adequate turbulence models is extremely challenging.

Nonintrusive Flow Diagnostic Methods

Research within the area of fluid dynamics over the last decade has resulted in the conception, development, and validation of a wide array of powerful new tools. In the experimental arena, the development of nonintrusive flow diagnostic methods, such as particle imaging velocimetry (PIV), holographic interferometry, and luminescent paints, is revolutionizing the study of fluid mechanics.

Computational Method

Computationally, developments such as unstructured and Chimera grids, direct and large eddy simulation (LES), and high-speed parallel computers, have provided the capability to analyze complex fluid dynamics problems which previously were not amenable to analysis. Advances in smart materials, microelectromechanical systems (MEMS), fuzzy logic, and neural networks offer the possibility of fluid mechanics control for a variety of Army systems. The application of these new tools to important Army fluid dynamics problems enables significant performance and life cycle cost improvement for many Army systems.

Research within the Fluid Dynamics Program is focused on the use of these tools for fundamental understanding of the complex fluid dynamics processes underlying these systems and involves analytical, computational, and experimental approaches.

Rotorcraft

Increased performance demands on modern Army rotorcraft require the accurate prediction and control of the forces and moments generated on the vehicle in hover, forward flight, and maneuver. Accomplishing this broad objective requires, for example, research into the mechanisms underlying unsteady separation of boundary-layer fluid on the suction side of rotorcraft blades, wakes, unsteady rotor aerodynamic loads, interference aerodynamics, and computational fluid mechanics. Typical examples of ongoing research within this field are the experimental and numerical determination of the flowfield over airfoils undergoing two- and three-dimensional unsteady separation with subsequent dynamic stall, the use of nonintrusive experimental techniques, and the development of efficient computational methodologies to accurately determine the flowfield induced by the main rotor on the helicopter fuselage- empennage-tail rotor, and the development of advanced rotor free-wake methods to improve predictive capability for helicopter performance, vibration, and noise.

Projectiles

To ensure the accuracy and range of unguided gun-launched projectiles and the maneuverability and lethality of guided munitions and rockets, a thorough knowledge of the forces and moments acting during both launch and free flight is required. These objectives dictate research on shock boundary-layer interactions, compressible turbulence modeling, aft body-plume interactions, vortex shedding at high angle of attack, transonic body flows, and aerodynamic interference effects between various missile components. The general research areas of turbulent flows on spinning bodies, multi-shocked flowfield structure, base drag analysis and reduction, and control jet-flowfield interactions are also relevant to this research program. Examples of current studies in this subfield are the experimental study of aft body-plume-induced separation, the use of direct numerical simulation, LES, laser-Doppler velocimetry (LDV), and PIV techniques to investigate axisymmetric supersonic power-on/ power-off base flows, and the experimental investigation into the underlying physics of unsteady shock-wave /turbulent boundary-layer interactions.

Introduction (Air Force)

Air Force basic research in fluid mechanics seeks to enhance the performance and reliability of aerospace vehicles by developing new capabilities for predicting and controlling the fluid dynamic and thermodynamic behavior of complex flows in flight regimes and propulsion systems affecting Air Force operations. This research seeks to understand essential physical phenomena, to develop methods and models to predict them, and to create innovative strategies to expand the boundaries of flight by controlling these phenomena.

Major thrusts include: 1) the development of computational methods for accurate and efficient numerical solution of the equations of fluid dynamics, especially for dynamic, unsteady, multi-body problems, 2) active flow control relevant to engine nozzle exhaust flows, mixing thrust vectoring, and high lift, 3) the aerothermo- dynamics of hypersonic flows, 4) the fundamental structure and dynamics of transitional and turbulent compressible flows, 5) the prediction and control of turbulence, and 6) the complex internal aerodynamics and thermodynamics of flows in gas turbine engines.

Turbulence

Aircraft manufacturers, AFRL directorates and test centers require improved, validated turbulence models. In fact, such models top the list of industry needs for fluid mechanics research and are a key pacing item for computational fluid dynamics. Research targets the high Reynolds number, compressible flows of interest to the Air Force, and seeks to develop large-eddy simulation (LES) methods and improved subgrid turbulence models for accurate predictions.

turbulence models top the list of industry needs for fluid mechanics research and are a key pacing item for computational fluid dynamics

Aircraft and weapon systems in maneuvering combat operate in environments far more hostile than those occurring under level flight. Weapons released in this environment have been known to hit the launch aircraft. Advanced Computational Fluid Dynamics (CFD) research is developing numerical simulation methods that predict the dynamic motion effects on aircraft systems and missiles. Research in multi-body CFD is developing computer simulation technology that can predict the trajectories of weapons as they release from an aircraft, reducing the danger to pilots who fly weapons certification tests. CFD research also focuses on understanding the fundamental causes of inlet unstart, the sudden shut down of engines on maneuvering supersonic and hypersonic vehicles.

Active Flow Control

Active flow control research explores fundamental flow instabilities and their control for potential application to thrust vectoring, engine controls, high lift, aero-optics, low noise, and several other critical areas. Low observable requirements fix jet nozzle exit geometry and require internal flow adjustments to optimize performance. Fluidic flow controls are being explored in this context. Innovative active flow control approaches also enable the development of advanced high-lift technologies for enhanced aerodynamic performance of stealth vehicle configurations. Active flow control may also alleviate currently uncontrolled sonic fatigue problems with the divergent nozzle flaps; those on the F-110 engine create one of the major headaches for logistics support of the F-16. Also, inadequate turbulent drag reduction strategies limit the potential for enhanced range and payload. Basic research approaches under exploration include innovative uses of microelectromechanical systems (MEMS) and neural networks, the generic issue being the management and control of vorticity production on aerodynamic surfaces. McDonnell Douglas is now exploring basic research results on jet control for supersonic jet noise reduction, fluidically controlled thrust vectoring, and paint removal processes. Boeing is exploring new aerodynamic testing methods based on recent basic research on microfabricated flow sensors.

Hypersonic Flight

Future hypersonic flight vehicles will operate at very high altitudes within the earth’s atmosphere to reach global targets. At these altitudes, the atmosphere is highly rarefied, and it is important to predict the character of these rarefied flows. Underpredicted drag and heat transfer can result in vehicles that will not reach their intended targets. Computational and experimental research aims at revealing the fundamental fluid mechanical properties of hypersonic, chemically reacting flow, providing better predictions of vehicle heating, directly leading to safe designs.

3D Flows

Maneuvering combat aircraft generate complex, 3-D spatially and temporally varying flows that are ingested by the propulsion system’s airbreathing engine inlets. The total pressure distribution of these complex flows entering the inlets become even more non-uniform, or distorted, as the flow passes through the inlet compression shock wave system. This distortion greatly reduces the total pressure of the flow that enters the compressor face for supersonic propulsion and turbomachine engine propulsion systems. The greater the distortion, the lower the engine thrust. Computational fluid dynamic research has been undertaken to predict the complex distortion fields which arise in supersonic and hypersonic air breathing engine inlets and inlet systems on maneuvering Air Force aircraft and missile weapons systems.

Flight Control

Current flight control systems intentionally limit the operational envelope of modern fighters to avoid entering the post stall environment during dynamic maneuvers. Unsteady aerodynamics research within this project seeks to develop the knowledge base to expand the predictability and controllability of flows in this environment. Another critical need is preventing the unsteady aerodynamic buffeting of vertical control surfaces on the F-15 and F-16 that leads to structural fatigue, loss of reliability and degraded supportability.

Engine Technology

A major concern of engine manufacturers, and the focus of the Integrated High Performance Turbine Engine Technology (IHPTET) Program is to improve the thrust to weight ratio of gas turbine engines. Improved compressor efficiency and stability are essential elements of this requirement. Problems with heat transfer in the combustor and turbine stages account for half the ten-year development time currently required for new engines. In addition, thermally induced fatigue failures in the F-110 combustor produce one of the largest maintenance problems for the F-16. Research within this project aims at improving our understanding of heat transfer in high turbulence environments, improving film cooling, and controlling the unsteady fluid dynamics dominating compressor performance and contributing to the problem of high-cycle fatigue.

Joint DoD Cooperation

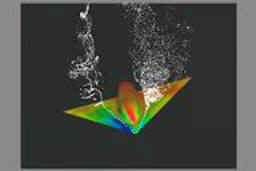

Through Joint DoD Cooperation, this Air Force research program is closely coordinated with Army and Navy programs. AFOSR fluid mechanics research focuses on central Air Force interests in high speed flows, compressibility, dynamic maneuverability, control of aerodynamic phenomena, and the fluid mechanics and thermodynamics of flow in gas turbine engines. In turn, the Navy focuses on hydrodynamic wakes and free surface phenomena. In the area of unsteady aerodynamics, the Army deals primarily with 2-D blade-rotor interactions relevant to helicopters, while the Air Force focuses on 3-D vortex dominated fluid-structure interactions relevant to aircraft maneuverability.

Introduction (Army)

Army systems and subsystems are designed for prescribed lethal effects and maximum protection levels along with agility and mobility at affordable costs. They are subjected to long-term effects under benign circumstances, as well as short-term catastrophic effects under hostile field conditions. Choices among a complex array of materials and manufacturing processes need to be made for the optimum tactical and logistical superiority. The flow, instability, and failure behavior of materials and structures under stresses caused by hygroscopic, thermal, mechanical, chemical, and electromagnetic constraints critically determine the future capabilities of our fighting forces.

the flow, instability, and failure behavior of materials an structures under stresses critically determine the future capabilities of our fighting forces.

The science of solid mechanics transforms the physical phenomena (deformation, instability, and failure) into algorithms for simulation codes through self-consistent mathematical constructs based on clean, tractable, laboratory-scale experiments. The products of fruitful research in solid mechanics are the models, which are integral to, but hidden in, the simulation routines. The reliability of displayed results, which are so important in design decisions, is never better than the ability of the model to portray the event as realistically as possible. Fundamental developments in solid mechanics are augmented by developments in physics and materials science, in diagnostic techniques to probe micromechanical phenomena, and in computational mechanics.

The major areas of interest for the U.S. Army Research Office (ARO) Solid Mechanics Program are micromechanics, finite deformation, instabilities (such as shear localization and cracks), stress wave propagation, damage mechanisms, and computational techniques to handle heterogeneities, steep gradients, and discontinuities. The results have applications to armor/anti-armor, weapons platforms, ammunition, and survivability considerations of Army materiel and personnel.

Failure and Damage Mechanisms

A thrust area of particular importance to the Army in the solid mechanics field is failure mechanism determination, assessment, and damage effects on structural performance. Particular emphasis is placed on structures performing in complex and aggressive loading environments where the coupling between micromechanics and overall material response must be considered in the design of more reliable Army equipment. Typical subject areas requiring emphasis are three-dimensional constitutive models that allow for path dependency, localization phenomena, failure processes induced by aggressive service environments, and the effect of many interacting inhomogeneities in structural materials. Scaling laws and the understanding of stochastic behavior in composite structures are potentially important topics to the Army.

Large amounts of deformation through nonproportional multi-axial loading paths are encountered in the fabrication of many armaments / missiles components, in the formation and flight of explosively formed penetrators (EFP) and shaped charge jets, and in the penetrator / target interaction zones. Conditions of strain rate and temperature are also heterogeneous. Nonlinear processes, such as the nucleation and growth of shear bands, are performance-limiting in some instances and are to be promoted in others. Understanding and parametric analysis of these processes is facilitated by the development of constitutive models and failure criteria. Rate-dependent finite deformation plasticity theory, evolution of texture, criteria for formation of shear bands, and nucleation, growth, and coalescence of voids and cracks are important technical issues.

Composite materials are serious contenders for a variety of Army materiel because of their superior stiffness and specific strength. They are also prone to defects during processing and service. Nonlinearities in structure-dependent behavior of these heterogeneous materials make design techniques, scaling, and service-life predictions very difficult but important issues.

Selected current research studies pursued in support of these areas in solid mechanics are experiments, analytical modeling, and numerical simulation of evolution of damage in structures; crystal plasticity and continuum treatment of large deformation at high strain rates; experimentally verified models for probability of failure modes in composites; high strain-rate deformation and failure in dual-phase composites; nonlinear behavior of functionally gradient materials; and micro-mechanics of anisotropic solids with inhomogeneities and cracks.

Impact and Penetration

Another major thrust is the determination of impact and penetration processes in both homogeneous and composite structures with special focus on the high strain rate phenomena and the resulting material failure sequences. Penetration mechanics is a subject that integrates the development of many subjects to provide a predictive capability. Physical understanding of the processes, models which can be simply verified in laboratory scale experiments but can be applied to field experiments by simulation, and numerical experiments with innovative techniques in computational mechanics are worthy of research pursuit.

A wide variety of Army materiel, such as helicopter blades, tactical missile structures, ground vehicle armor, and penetrators, are often subjected to impact loading covering the full spectrum of impact velocities and impulses. Vulnerability assessments and design of space- and weight-saving protection systems depend on understanding the mechanics of the phenomena. Ever-increasing demands for weight and volume efficient protective structures for armored vehicles need to be addressed by making use of every possible mechanism in traditionally passive materials. Energy absorbing mechanisms can be triggered by the stresses due to impact or disruptive mechanisms and can be instigated by external means in materials to affect penetration mechanics. The intent is to create a science base necessary for the exploitation of novel materials/mechanisms.

Topics in this area include stress wave propagation in solids, damage evolution in brittle/ductile materials, impact damage and penetration processes, and structures that retard the penetration process. Selected projects in the impact and penetration research area are focused on shear resistance and shear localization under high-pressure at very high rate for high-strength steels, tungsten alloys, and tantalum; finite element simulation of the penetration process in cases of depleted uranium (DU) or tungsten alloy through steel; failure criteria and failure mode transition in ductile materials; mechanics of long rod penetration into ceramics under confinement; materials modeling of shock-induced chemical reactions in nonenergetic powder mixtures; shock wave propagation through layered media; and shock-induced phase transformations.

STRUCTURES and DYNAMICS

Introduction (Army)

The interaction of inertial, elastic, impact, damping, and aerodynamic forces acting on armament systems, rotorcraft, missiles, and land vehicles is of fundamental importance to the design and construction of reliable, durable, and maintainable Army equipment with acceptable levels of personnel safety and comfort. As advanced weapons and mobility systems evolve to meet the demanding requirements of higher acceleration levels, greater loading rates, higher temperatures, and increased relative velocities among system components, greater attention must be devoted to the development of effective, high-quality military equipment that will withstand extreme battlefield conditions.

Thus, designers must assure the integrity of structures and machine components through an understanding of the stress and deformation states that result from a variety of complex loading mechanisms in the static and dynamic regimes. This understanding can be attained through the development of sophisticated mathematical models and effective, efficient numerical solution techniques validated through extensive experimental investigations. Consequently, ARO supports fundamental research in structural mechanics of composite materials, structural dynamics, control, simulation, and smart structures.

Of special interest is the new field of smart structures concepts applicable to the armor environment. Such resilient structures would combine the functions of sensing, actuation, and control in the space and time domain necessary to autonomously react to the impact and penetration event characteristic of armor attack, to provide resistance to the penetration/failure processes. Examples of phenomena to be examined for these innovative applications are shock-induced material reactions and resultant chemically changed compositions, phase transformation effects, and electro-thermomechanical processes that can be beneficially used for energy soak mechanisms.

Undesirable vibration levels occur in a variety of equipment used by the Army. An effective, innovative approach to quench such structural vibrations is the development of smart structural components that can automatically compensate for the excessive force levels applied to them. The concept of a smart structure is based upon the application of modern control techniques to structural elements fabricated from composite materials, in which actuators and sensors are embedded. Because of their directional strength properties, passive and smart composite structures can be tailored by engineers to optimize their dynamic response characteristics.

Structural Damping Techniques

Significant progress is also being made in the development of novel structural damping techniques that could have a significant effect on how helicopter rotor blades and weapons systems are designed. New schemes currently under investigation include magneto-rheological and electro-rheological fluid based damping devices, active constrained layer damping treatments, piezoceramic actuators bonded to a structure and coupled to a shunted electric circuit, and nonlinear controller facilitated energy dissipation through an electronic circuit. Other new approaches, such as distributed control techniques (in contrast to controllers for discrete systems), localization and isolation of modal response, delayed action vibration absorbers, and neuromuscular-like control for absorbing structural vibration energy, may offer opportunities for progress in vibration control in the future.

Structural Mechanics of Composite Materials

Engineers require refined theories of elastic structures and improved, precise, and efficacious analytical and numerical procedures to design complex structures, frequently fabricated from advanced composite materials that can endure, without structural failure, repeated intense static and/or dynamic loading regimes. Many modern mechanical systems consist of combinations of rigid and deformable structural components that are lightweight and strong, but sometimes brittle. Therefore, a highly relevant problem is that of the mathematical modeling of anisotropic and laminated composite beams, plates, and shells. The new theory under development features the inclusion of geometrically exact kinematical equations, accounting for the presence of delaminated zones, and a general sectional modeling analysis methodology. This research offers the Army the capability of analyzing the static and dynamic behavior of highly complicated structures, such as those used in land vehicles and helicopter rotor blades.

The helicopter and automotive industries are today using composite materials in their new vehicles more frequently than previously because of their great strength, relatively lightweight, and advantageous thermal and electrical conductivities. The experienced load spectrum in the Army application is extremely broad. Fiber reinforced composites are being studied for use in hingeless and bearingless helicopter rotor blades. These blades can be used with rotor hubs that are significantly less complicated and expensive than the mechanically complex hubs currently in use with articulated rotor blade systems. Aeroelastically tailored composite rotor blades offer significant potential for improved stability, reduced vibration,

simplified hub design, and improved handling qualities of rotary wing vehicles. Advance- ments in each of these fundamental technical areas can lead to enhanced reliability, maintainability, personnel safety, and system performance. Development of new analytical tools to predict the complex dynamic behavior of these rotor systems is essential to the successful integration of tailored blade technology into next generation rotorcraft systems.

As an example of timely research in this area, a current investigation is focused on the development of a new composite rotating box beam model (for helicopter rotor blades) with embedded piezoelectric actuators based on a refined higher order laminate theory. The theory includes the effects of imperfections such as delamination and debonding of actuators. Analytical and numerical results reveal that embedded piezoelectric actuation significantly reduce the deflection along the box beam span and can be used to control the magnitude of blade vibrations. In extreme cases, the actuation can compensate for almost all deflections along the span due to blade weight and external loads.

Structural Dynamics and Simulation

This area of activity is focused on ground vehicle and multi-body dynamics, structural damping, structural controls, and inflatable structures. Key problems are the determination of the transient and steady state response of structures that are subjected to forces such as gravity, damping, aerodynamic influences, and electric fields. Because of the magnitudes of the loads exerted on Army equipment and the need to reduce weight to enhance performance and range, it is essential to include the deformation characteristics in the mathematical models developed to describe system behavior. Numerous large and complex mechanical systems used by or for the Army consist of interconnected multi-body structures, such as heavy machinery, wheeled/tracked military land vehicles, robotic equipment, machine tools, rotorcraft, vehicle engines, power transmissions, communication devices, and automatic weapons. To design such structures efficiently and effectively, kinematic and dynamic simulations of flexible multi-body systems based on constrained non-linear dynamics are required. In particular, recent advances in computers, graphics, and communication are undergirding recent developments in motion based simulators with computer generated imagery that interface vehicle dynamic models and their physical environments.

Such computer simulations predict the kinematic and dynamic behavior of multibody systems in considerable detail, providing sufficient data to study the influence of a variety of design parameters and to determine the detailed evaluations of concept performance capabilities. Examples of current research programs include the development of (1) a non-linear dynamics analysis of tracked vehicles that includes the interaction between the track links and the ground, the sprockets, the idlers, and the rollers of the tracked vehicles; (2) a novel active structural damping technique using piezoceramic actuators and non-linear controller concepts to suppress transient and steady bending and torsional vibrations of flexible structures; and (3) a refined analysis capability for electroded piezoelectric plates, which yields highly numerical values of resonance frequencies for AT-cut quartz plates that are desired for advanced radar and communications systems because of their frequency stability against temperature fluctuation and acceleration induced stresses.

Smart Structures

A smart structure is defined to be a structure that contains embedded sensors and actuators with associated control system capabilities enabling it to respond in real time or nearly real time to external stimuli in proportion to their intensity to compensate for undesired effects or to enhance desired effects. The application of the smart structure concept offers the potential for the development of a new series of structural systems that may find application in modern rotorcraft, land vehicles, weapons systems, aircraft, submarines, spacecraft, and industrial machinery. To realize the promise of such active structures, additional research is required into the fundamental understanding of how they function and how they can be controlled. Hence, engineers and designers must know how to create the next generation of active materials that can serve as effective sensors and actuators, how to express appropriate constitutive equations, how to derive their equations of motion, how to design efficacious controllers, etc. This knowledge will permit Army engineers to suppress the vibrations in machine gun barrels and rotorcraft structural components; augment aeromechanical stability; enhance rotorcraft handling and maneuverability qualities through the change of a rotor blade’s camber; reduce blade-vortex interaction noise levels in rotorcraft; and detect structural damage, such as material fracture, debonding, and delamination.

The application of the smart structure concept offers the potential for the development of a new series of structural systems that may find application in modern rotorcraft, land vehicles, weapons systems, aircraft, submarines, spacecraft, and industrial machinery.

The most prominent actuation techniques suggested for smart structures are based on the properties of piezoelectric ceramics and films, shape memory alloys (such as nitinol), electro-rheological fluids, electrostrictive materials, and magnetostrictive materials (such as terfenol-d). However, it may prove necessary to devise hybrid actuators formed by combining the properties of two or more actuating substances or to consider optimized actuator configurations that deliver greater force or displacement levels.

As an example of research in this area, researchers are developing a layered piezoelectric actuator in a semi-circular or C-shaped configuration that produces greater force and deflection levels than conventional piezoceramic stacked or flat bimorph actuators. It is being tested in an active helicopter rotor blade flap system, where it will be used in higher harmonic or individual blade control systems. These C-shaped actuators can be arranged in series and/or parallel to tailor the force and deflection generated. This C-shaped actuator will produce flap deflections sufficiently large (up to ±10) to provide significant reductions in rotor blade vibration amplitudes. The actuator model is generic and can be used to design optimized C-shaped actuators for missile flap control surfaces for flight control and suppressing vibrations of machine gun barrels.

Recent research has revealed that composite structural materials with embedded shape memory alloy wires offer significant increases in energy absorbing ability and penetration prevention capability. Experiments revealed that the shape memory alloy wires have a considerable effect on the load deflection behavior. For example, a 41 percent increase in absorbed energy over the bi-directional plain graphite lay-up was observed in the 6 percent volume fraction unidirectional shape memory alloy bi-directional graphite hybrid. These configurations offer penetration prevention but not increased damage resistance. Therefore, they have potential use in such applications as personal body armor and lightweight shelters.

Solid Mechanics and Structures (Air Force)

This area of research seeks to develop a fundamental understanding of the behavior of aerospace materials, structures, and supporting facilities, leading to the cost-effective development and safe, reliable operation of superior weapons and defensive systems. Research includes such diverse topics as the micromechanical design of advanced materials, modeling and simulation of the dynamic behavior of aircraft, missiles, earth penetrators, airfield pavements/facilities, and large space structures, and the technology integration for the performance and survivability enhancement of these systems.

The mechanics research sponsored in this project is closely coordinated with research performed under Structural Materials, which considers the materials science processing aspects of modern aerospace structural material systems, and research performed under Fluid Mechanics, which considers basic research issues associated with turbulence modeling and hypersonic flight.

Future aerospace engine and airframe structures will be composed of advanced, fibrous materials capable of extended operation in severe environments. Research in the mechanics of materials area seeks to understand the fundamental behavior of these material systems to facilitate the development of accurate design and life prediction methodologies. The development of these materials will allow the design of faster, more efficient aircraft and spacecraft. These advanced materials are also enabling technology for future Air Force initiatives such as hypersonic aircraft, which can potentially take off from conventional runways and achieve global orbit, and highly maneuverable uninhabited aerial vehicles (UAVs). Current project thrusts include understanding the fracture behavior and thermomechanical behavior of high temperature composite materials, such as ceramic- matrix composites, metal-matrix composites, carbon-carbon composites.

Scientific issues include improved fiber/matrix interfaces, durable coating systems, and improved design methodology and life prediction systems based on material damage growth mechanisms. Results from this program are being used by Northrop-Grumman to understand matrix cracking and fiber/matrix interface failure in ceramic-matrix composites. AFOSR researchers are also studying innovative heterogeneous material systems, such as textile composites, functionally-graded materials and nanostructural materials as well as functional materials for smart structure applications.

Service Life

The extended service life for many existing systems also requires further research to understand how materials and structures behave after very long periods of service. Factors such as corrosion and multiple-site damage serve to reduce the load-carrying capability of aging Air Force aircraft. This area seeks new methods of nondestructive evaluation (NDE) of these systems to detect internal cracking and/or corrosion in a quick and reliable manner, and to provide improved life prediction methodologies. Results from this research are being used by the Air Force Research Laboratory to understand the effects of corrosion and fatigue on the safety of aging aircraft structures.

Particulate Systems

The goal of the particulate and fluid mechanics research program is to develop a first principles understanding of the behavior of particulate systems and their interaction with the surrounding environment. The first principle thrust focuses on understanding the mechanical behavior of multiphase particulate systems. Particulate materials are defined as those that can be represented as an assemblage of physically discrete particles – either alone or in a matrix material having significantly different properties. Particulate materials of interest include soils, rock, concrete, asphalt, and engineered nanoparticles.

The specific research objectives are to understand: 1) the influence of material microstructure on overall macroscopic constitutive behavior; 2) the constitutive behavior of multiphase (heterogeneous) particulate systems; 3) the localization and instability in particulate media, including their potential to flow and liquefy; 4) effects of material interfaces; 5) damage accumulation and penetration mechanics of geomaterials; 6) effects of new chemical compounds released into the subsurface environment; and 7) transmission and attenuation of electromagnetic and seismic waves in geomaterials.

Particulate mechanics research examines particulate systems with characteristic lengths that range from nanometers to meters. Efforts seek to obtain quantitative relationships to describe the fundamental mechanics governing the behavior of particulate systems, for example the behavior between individual constituents and between the aggregate assembly and the surrounding environment in response to an external load. Efforts involve multidisciplinary theoretical, analytical and/or experimental approaches from disciplines such as engineering mechanics, material science, physics and applied mathematics. Constitutive models that incorporate the microstructural behavior of these heterogeneous anisotropic multiphase discrete systems are theorized and experimentally demonstrated.

Particulate materials are ubiquitous, hence the research products from this program will have a scientific impact on a diverse range of end users. This research will provide a knowledge base from which analytical models can be developed to design and evaluate new material processing technologies, and hence, more affordable aerospace structural materials. Direct benefits to the military services include real-time subsurface target detection and damage assessment on the battle field, improved earth penetrators and precision guided munitions effectiveness, enhanced structural survivability and vulnerability and “smart” infrastructure supporting systems capable of surviving extreme blast loading. Much of the technology supporting these needs has been based on empiricism. Therefore, the scientific contribution of this program will be a physically based understanding of the behavior of a range of materials and analysis techniques to predict their response to new loading regimes.

Structural Mechanics

The focus of the structural mechanics program is to investigate fundamental structural principles over a broad length scale (i.e., nanometer to meter scale). At the high end of this scale, an understanding of the aero-structural and structural-acoustic behaviors of airframe, engine structures and launch vehicles is desired. Nonlinearities in these systems are traced to the interaction of fluids and structures, large amplitude vibration, system nonlinearity due to damping, and other phenomenon. This research is expected to provide engineering information on airframe failure from fluid flow disturbances and engine stall due to pressure variation. This research seeks to provide answers to many system operational issues. Examples include limit cycle oscillations and flutter on fixed-wing aircraft, engine compressor instability and turbine failure.

Results of this research have been used by the Cessna Aircraft Company to predict the onset of flutter, understand post flutter behavior, and develop active flutter control techniques. Also, researchers in the universities are working with Air Force Research Laboratory and the Aeronautical Systems Center (ASC) on these operational problems.

Smart and composite structures research involves coupling nonlinear structural mechanics principles with advanced materials development, fluid mechanics, control theory, and sensor/actuator technology, such as smart materials and microelectromechanical systems (MEMS). This research will lead to the development and design of real-time monitoring and self-correction techniques for enhancing system performance. For example, intelligent materials and active structures are being developed which can continuously monitor damage formation and growth in current and future aerospace structures. Continuous shape control of aerodynamic surface may also be possible through a precise distribution of sensors and actuators.

The anisotropy, inhomogeneity, and damage characteristics of emerging structural material systems dictate the development of new solid mechanics and structural analysis principles critical for performance prediction and material synthesis. Traditional mechanics of materials principles do not capture the fundamentals that dictate the behavior of these advanced material systems. One aspect of the structural mechanics program is to expand the fundamental knowledge base to better understand the mechanics of deformation and damage of aerospace structures. For example, engineers at both NASA and Goodyear Tire Company are applying computational methodologies developed under this program to understand nonlinear deformation of aircraft tires that lead to excessive wear.

Summary DoD

In summary, research in solid mechanics and structures is necessary for the design and operation of future Air Force weapon systems, as well as the continuing operation of existing systems, which are currently projected for use well beyond their original design lifetimes. Under the Reliance Agreement, the Air Force has the lead responsibility for the mechanics of high-temperature structural materials and particulate material systems and fixed-wing aeroelasticity. The Army has primary responsibility for research in impact / penetration mechanics, and rotary-wing aeroelasticity, while the Navy is the lead service in the mechanics of thick-section composites, structural acoustics, and hydroelasticity.